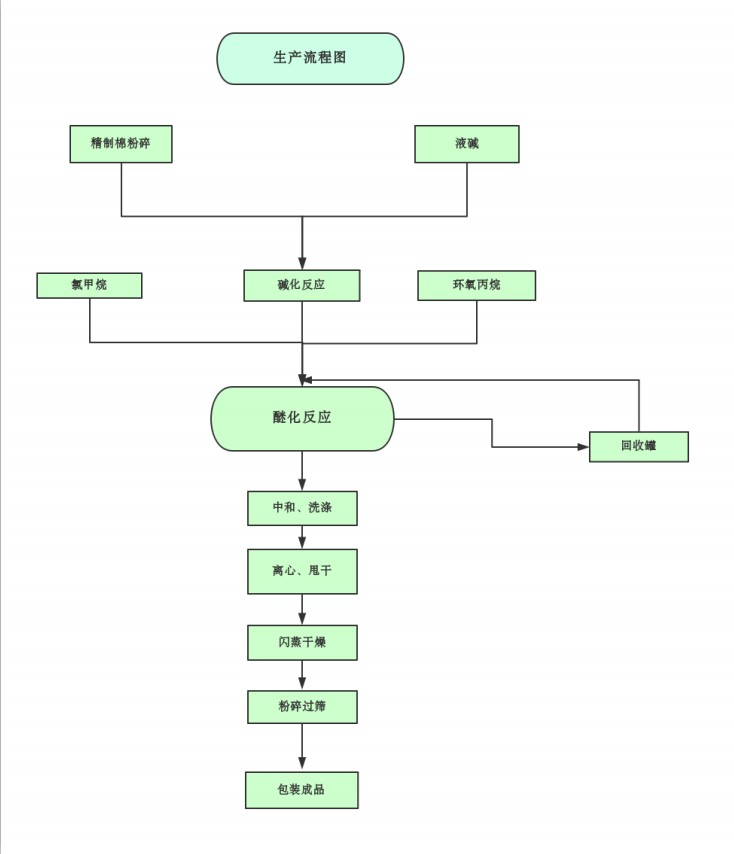

Production process and flow of hydroxypropyl methyl cellulose

Refined cotton - cotton opening - alkalization - etherification - neutralization - Separation - washing - Separation - drying - crushing - Packaging - finished hydroxypropyl methylcellulose: loosen the refined cotton to remove iron, and then crush it. The pulverized refined cotton is powdery, with a particle size of 80 mesh and a transmittance of 100%. Otherwise, it is easy to agglomerate in the reaction process and reduce the etherification efficiency.

Alkalization: the powdered refined cotton after cotton opening is added to the inert solvent and activated with alkali and soft water to make the lattice of the refined cotton swell, which is conducive to the penetration of etherifying agent molecules and improve the uniformity of etherification reaction. The alkali used for alkalization is metal hydroxide or organic alkali. The addition amount of alkali (by mass, the same below) is 0.1-0.6 times that of refined cotton, and the addition amount of soft water is 0.3-1.0 times that of refined cotton; The inert solvent is a mixture of alcohol and hydrocarbon. The amount of inert solvent is 7-15 times that of refined cotton. The inert solvent can also be alcohol with 3-5 carbon atoms (such as alcohol, propanol) and acetone. It can also be aliphatic hydrocarbon or aromatic hydrocarbon; During alkalization, the temperature shall be controlled within 0-35 ℃; The alkalization time is about LHR. The temperature and time can be adjusted according to the requirements of finished materials and products.

Etherification: after alkalization treatment, etherification is carried out by adding etherifying agent under vacuum. The etherifying agent is propylene oxide. In order to reduce the consumption of etherifying agent, etherifying agent is added twice in the etherification process. The first addition amount is 1-3.5 times that of refined cotton, and the total amount added twice is 1.5-4 times that of refined cotton. After adding etherifying agent for the first time, first stir at ≤ 30 ℃ for 45min-90min, then raise the temperature to 50-100 ℃ for etherification for 1-5h, and then lower the temperature to ≤ 30 ℃. For the second time, add etherifying agent for stirring for 30-120min, then raise the temperature for etherification for l-4h. At this time, the refined cotton fully reacts with etherifying agent, Hydroxypropyl methylcellulose is produced.

Crushing and packaging: the dried product of the invention is crushed and sieved. The particle size of the product of the invention after crushing and sieving is 40 mesh and the transmittance is 96%, or according to the needs of users. Then hydroxypropyl methylcellulose is packaged and delivered.

{aspcms:comment}